-

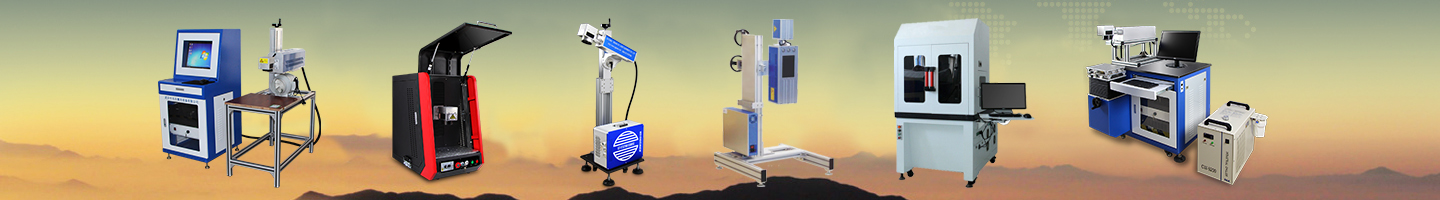

Laser engraving cutting

Laser engraving machine to improve the efficiency of the carving,

MORE>>

so that the surface of the carved smooth, rounded, quickly reduced the temperature of the carved non-metallic materials to reduce the deformation of the carved and internal stress;

can be widely used for a variety of non-metallic Materials for fine engraving areas. -

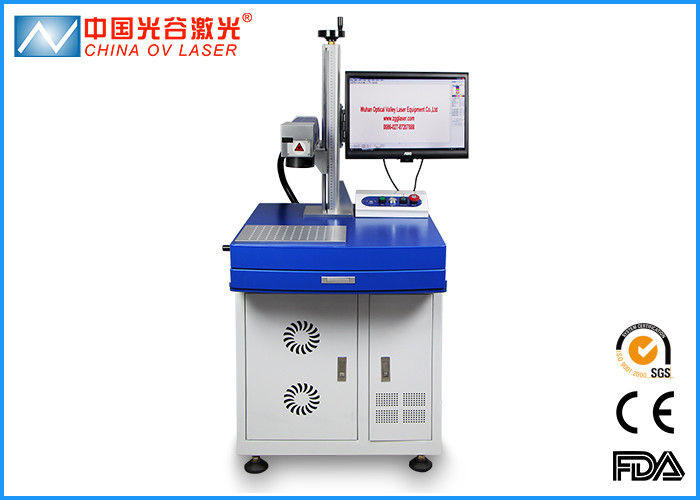

Laser marking machine

Laser marking is marked with a

MORE>>

laser beam on a variety of different material surfaces.

The effect of marking is to expose the deep material through the evaporation of the surface material, or to "mark" the trace by the chemical and physical changes of the surface material,

or by burning some of the material by light. Pattern, text. -

Laser cleaning machine

The pulsed Nd: YAG laser cleaning

MORE>>

process relies on the characteristics of the optical pulses generated by the laser, based on the physical principle of the photophysical reaction caused by the interaction between the high intensity beam, the short pulse laser and the contaminant layer Summarized as follows:

The laser beam emitted by the laser is absorbed by the contaminant layer on the surface to be treated.

The absorption of large energy forms a rapidly expanding plasma (highly ionized ... -

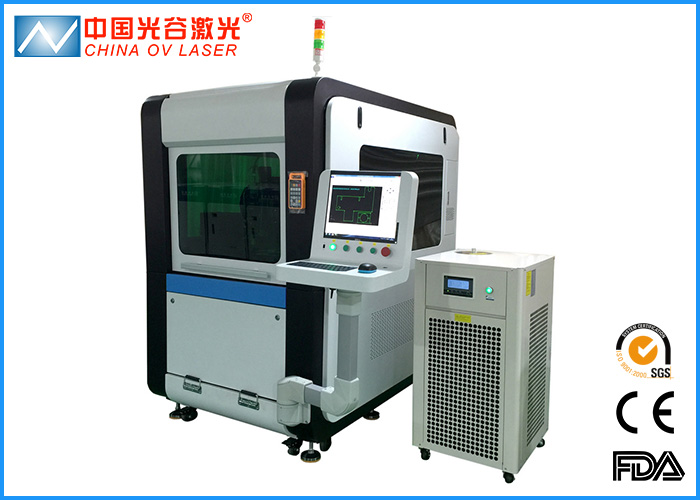

Metal laser cutting

Metal laser cutting machine is the use of high-power density of the laser beam scanning the surface of the material in a very short period of time the material heated to thousands of degrees to tens of thousands of degrees Celsius,

MORE>>

the material melting or gasification, and then high-pressure gas will melt or gasification from Cut in the cut, to achieve the purpose of cutting materials.

Laser cutting, because it is the use of invisible beam instead of the traditional mechanical knife, the ... -

Laser welding machine

Laser welding is the use of high-energy laser pulse on the material in a small area of local heating,

MORE>>

laser radiation through the heat conduction to the internal diffusion of materials,

the material melts to form a specific pool. It is a new type of welding, mainly for thin-walled materials, precision parts of the welding, can achieve spot welding, butt welding, stack welding, sealing welding, high aspect ratio, small weld width, heat affected area is small, Deformation is small, welding ... -

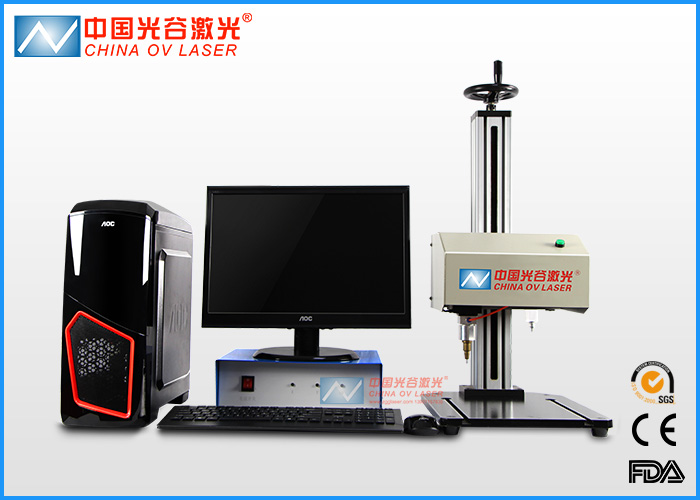

Pneumatic marking machine

Pneumatic marking machine is made up of the main engine, control box, computer and software.

MORE>>

It is controlled by the computer. The needle is moved in the XY two-dimensional motion mechanism according to the software, and the printing needle is under the action of compressed air For high-frequency vibration shock, so in the workpiece plane,

the curvature of the small arc or cylindrical axis to print out a clear, standardized, beautiful logo. -

Nameplate embosser

The plate embossing machine is composed of a driving control system, an electro-engraving mechanism, an industrial grade XY sign device, a word plate, a computer and a software,

MORE>>

which is driven by a computer and a driving control system to drive the sign device and the sign in XY plane motion,

computer control Word plate rotation of the selection of characters, the use of brushless motor, reducer lever mechanism top pressure font, which in the signs on the embossed concave and convex has ... -

Nameplate welding machine

Iron and steel production, especially in the production of bar,

MORE>>

the finished product signs are generally fixed with wire or strip signs on both ends of the surface, so that in the process of moving the signs easily lost,

to provide illegal counterfeit manufacturers opportunities.

At the same time bundles of bar in the production, sale, storage process is generally stacked into the stack, the signs were buried in the stack caused by the relevant technical parameters of the signs can not ...

Address:Wuhan Optical Valley in laser equipment Ltd.

switchboard:?86-27-87207888??Extension;86-27-87207888Turn8188??8288

Marketing Center:?86-27-83566512??83566502??83566517??13707157835

Navigation | Disclaimer | china?ov?Wuhan Optical Valley in laser equipment Ltd.All rights reserved 鄂ICP備15003120號-1